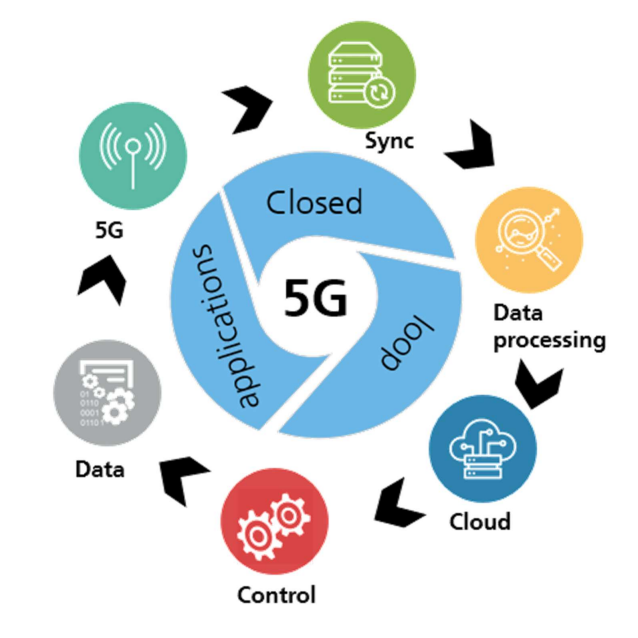

Due to many upcoming manufacturing challenges like shorter-time-to-market times, high quality and sustainability requirements on products and automation and digitalization aspects in processes, closed-loops in manufacturing are becoming a cornerstone for industry. In combination with 5G technology, high reliable and flexible data-driven and adaptive production with closed-loops might be possible.

| Topic Fields | |

| Published | 2021 |

| Involved Institutes | |

| Project Type | ICNAP Community Study |

| Result Type | |

| Responsibles |

In the frame of this study “5G for closed-loop manufacturing”, different aspects of 5G closed-loops in manufacturing were discussed. Within the first workshops a classification of manufacturing use cases for 5G closed-loop systems has been investigated. The following four categories were defined: 1. Real-time process monitoring and control with wireless sensors 2. Quality Check in real-time for process control 3. Cloud, High performance server, external computation power 4. Flexibility & Mobility Regarding the requirements for closed-loops, two main criteria were identified: security and reliability. Other requirements like mobility, latency, data rate or flexibility are strongly depending on the specific use case.

Contact us to get in touch! With a membership, you’ll gain full access to all project information and updates.

© Fraunhofer 2025